► JLR take the dual-clutch box off-road

► Developing first 4×4 eight-speed DCT

► Here’s how it works

Land Rover is developing the world’s first eight-speed dual-clutch transmission optimised for off-road use.

DCTs are effectively two gearboxes in one, with one clutch controlling the odd gears and the second clutch the even gears, connected to the engine in turn depending on which gear is engaged. An output shaft from each gearbox applies torque to the driven wheels via the differential. Electronics pre-determine the next cog and hydraulics engage it ahead of the shift itself, for seamless progress.

There’s a lot of activity on DCTs: pioneering VW is working on a 10-speed ’box with a torque capacity up to 405lb ft; JLR’s can supposedly handle 442lb ft, more than enough for punishing off-road durability testing.

1) Wide range for max control

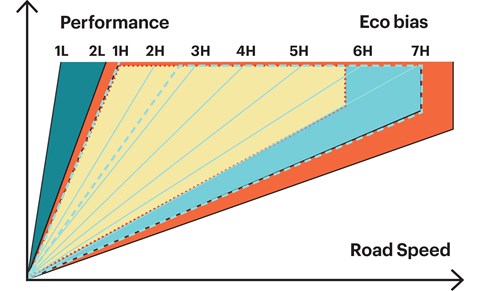

Codenamed POLAR 3, the geartrain layout offers a number of potential advantages, such as the wide ratio spread of just over 17 between top and bottom gear (see graphic, right); the Audi TT’s spread is 10.577. JLR’s DCT, in combination with very low range, should lead to Land Rovers with even better off-road attributes as the driver should have seamless access to the correct gear for the environment, plus additional control features through the Terrain Response selector.

2) No need for a transfer ’box

In the past, low-ratios for off-roading were manually selected by a transfer box, essentially a second gearbox that doubles the number of gears; trouble is, it’s tricky to operate on the fly with most drivers stopping to engage high- or low-ratio. Having a wide ratio spread, with very low gears for high torque and off-roading, and high gears with low torque for cruising, means a transfer box isn’t required; mimicking its function gives the DCT high- and low-range reverse gears too.

3) It’ll boost economy by 10%

Because the gear train layout is simpler and the clutches are locked, there will be some fuel savings. JLR’s powertrain research confirms ‘efficiency improvements’ but

says it’s too early to be specific. Typically, a six-speed DCT is about 10% more efficient than a five-speed torque converter auto.

4) Lubes for extreme angles

Currently the ’box uses ‘wet’ clutches, but production versions would likely use a ‘moist’ or ‘damp’ system with variable oil flow cooling. This ensures that extreme off-road manoeuvres can be maintained but with drag levels significantly reduced over a continuously ‘wet’ design.

5) Which engines and when?

A modular design means the front-drive take-off can be removed for use on rear-drive Jags, and hybridisation is feasible, along with a ‘sailing’ mode to decouple the engine during coasting to save fuel. Likely engine pairings will be the Ingenium I4 units and the 3.0-litre V6 turbodiesel. Land Rover is being coy on when the ’box might appear but the new Defender, expected around 2018, would be an ideal showcase.