► Jaguar and Williams team up for Formula E

► Will give Jag a real-world test bed for future EVs

► How relevant is Formula E to road car development?

Jaguar will return to frontline motorsport in September, when a new works team enters the third season of the electric Formula E race series. The programme will be used to fast-track electric vehicle technology for production cars, rather than just the old-school ‘win on Sunday, sell on Monday’ marketing approach, says Jaguar Land Rover’s group engineering director Nick Rogers.

‘We see this as an extension of our research and development functions,’ he told CAR at the project’s launch. ‘Obviously with new vehicles we’re always looking at pushing the boundaries of real world performance. The key part to Formula E for Jaguar is efficient use of energy – that’s the absolute [cornerstone] of the series and that’s why we like it; making sure we get the maximum amount of energy from the motors for acceleration, recouping energy under deceleration, while the control management system is absolutely vital. This race series is like an accelerated real world test, pushing the boundaries.’

Those engineering developments will benefit both Jaguar and Land Rover, although management is being coy with details of production EVs. However, CAR understands that Jaguar is well advanced with a bold-looking, all-electric crossover, which is pencilled in for assembly at Magna Steyr’s Austrian plant from 2018.

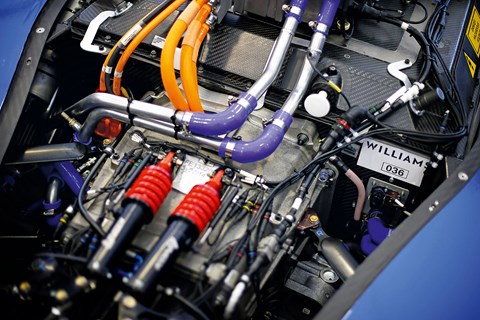

JLR’s Formula E team will collaborate with Williams Advanced Engineering, its partner in the stillborn C-X75 hybrid supercar project. ‘We learnt lessons about hardware and battery systems in C-X75, and a lot of the technology is very similar,’ explained team director James Barclay. He also revealed that Jaguar would be depending on Williams F1 know-how to run the team trackside and help with driver selection.

While Jaguar had been evaluating other forms of motorsport, including the World Endurance Championship, JLR’s directors believe that Formula E will not only speed up development of its own EV technology but is more relevant as the brands move toward electrification. ‘Formula E is a new platform appealing to a [younger] generation of spectators and car buyers [open-minded to] EVs, with races held in major cities around the world; we think that many of those conurbations will be early adopters of legislation demanding EVs in urban areas,’ said a JLR source.

The demise of the Trulli team freed up grid space for Jaguar. It joins Audi (ABT Schaeffler), Renault (E.Dams), Mahindra and DS (Virgin Racing) as the fifth car maker in the series.

Despite the fact that all the other teams have two seasons experience under their belts, Rogers is confident the squad will be competitive when it joins the series in the autumn. ‘The propulsion system is effectively open and we will be going in with our own system,’ he says. ‘To be honest we haven’t fully understood how we want to do that. There’s a lot of work to do.’

How it all works

1) Battery technology

Current 28kWh batteries will have to double in capacity to allow the cars to run the entire length of the 50-minute event at racing speeds without stopping in season five. At present, drivers swap cars half way through the race when the lithium-ion batteries are depleted.

2) Battery management

Keeping temperatures below 60°C is vital if the battery isn’t going to overheat. Critical in harvesting energy under braking and deploying it for maximum acceleration, while eking it out to ensure the racing driver doesn’t suffer the ignominy of coasting to a halt with a drained battery.

3) Tech to get an edge

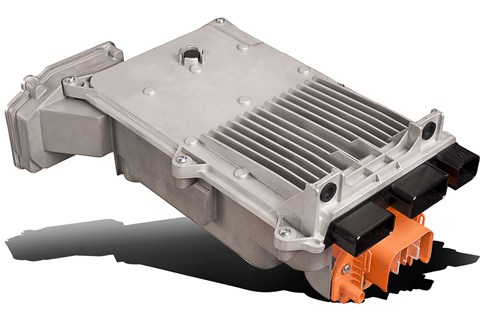

As race regulations free up, bespoke transmissions will be allowed, and Jaguar/Williams will be permitted to develop E-motors and inverters that will cross into production EVs. Rivals will be allowed to buy the powertrains at a capped cost, to prevent big name spending dominating smaller rivals.

4) Chassis and aero

Currently all the cars share the same chassis and aerodynamic package but by the fifth season teams can develop their own wind-cheating solutions. Experience with lightweight carbonfibre structures will translate into production cars.

Read more CAR tech news and features here