► Next A8’s chassis and suspension tech

► Enables ‘agility you wouldn’t expect’

► Carving into corners could be next

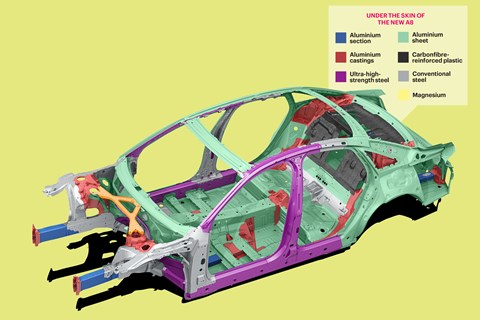

The bare body shell of this summer’s new Audi A8 has gained 51kg over its predecessor, tipping the scales at 282kg.

But – and it’s a big but – without the exotic combination of 28 materials joined together using 14 different techniques, the weight would have ballooned way beyond this figure.

Why gain weight when the aim in recent years has been slimming down? Tim Hämmerle of Audi’s Lightweight Design Centre explains that it’s the result of a perfect storm of unavoidable demands facing the makers of any luxury car: it’s slightly bigger; it has to be ready for more stringent crash regulations; it has, for the first time on an A8, a full-length glass roof; and it needs to protect and house heavy lithium-ion batteries and other ancillaries for future hybrid or electric versions.

Those 28 materials can be broken down into various grades of aluminium sheet, sections and castings, as well as conventional and hot-formed ultra high-strength steel (UHSS), a magnesium brace between the front bulkhead and suspension struts and, in a first for the brand, a

carbonfibre-reinforced polymer (CFRP) rear panel.

Check out the full details on the all-new Audi A8

Joining processes include newly developed aluminium-to-aluminium laser welding, different riveting systems, bonding and roller hemming, where aluminium and steel are wrapped together to form slim profiles around the door apertures and windscreen.

As a result Audi clams the saloon’s dynamic stiffness is increased by 24% and its front-end stiffness by 14%.

Laser welding

Laser-beam welding is used in both the lower sills where it joins steel to steel and the upper cantrail for aluminium to aluminium bonding to form a zero-gap roof joint. As well as being 53% faster than the old process it emits 24% less CO2 during assembly and, because no additional materials are used in the joining process there’s half as much thermal input.

Magnesium cross brace

Tying the bulkhead and suspension towers together, this brace is 33% less dense and 28% lighter than its predecessor. By using die-cast internal ribbing, engineers have managed to shave off a further 500 grams. Aluminium bolts secure it to the strut towers.

Roller hemming door apertures

Aluminium panels are progressively wrapped around the steel inner core in three 30° steps then pinched into place by pierce locking. This releases valuable millimetres of space, improving the door opening height by 14mm and width by 36mm. The A-pillar profile has been slimmed down, improving the driver’s view by 5°.

Carbonfibre-reinforced polymer rear panel

Manufactured using a faster version of a lay-up process similar to that used in aerospace, the 2.6kg CFRP panel contributes 33% to the car’s overall stiffness. It’s made up of 5cm-wide tapes precisely located to absorb longitudinal and transverse loads as well as shearing forces.

Biomimicry

Those with good memories might recall Mercedes’ Bionic concept from 2005, a car designed along the lines of the efficiently shaped boxfish. It didn’t turn into anything, but nature is inspiring engineers to mimic its lightweight and high strength as found in bird’s bone structure. The A8 uses twin 143cm beams under the boot floor, featuring thin wall lattice castings in structures that are 50% stiffer than other designs.

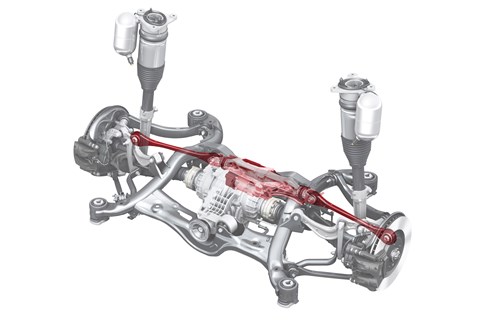

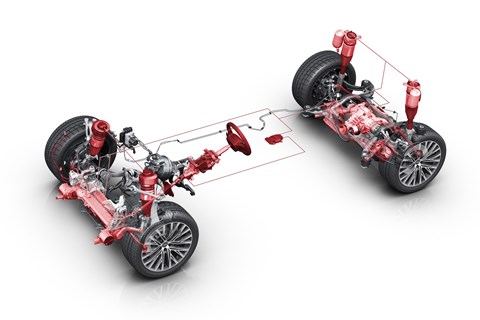

New Audi A8’s suspension explained

Thanks to its 48-volt architecture the new Audi A8 is shaping up to be the company’s most technically advanced car to date.

The latest tit-bit to be drip-fed from Ingolstadt ahead of the car’s official reveal this summer is a detailed look at its new active suspension system. However, unlike the massively expensive and, relatively, heavy hydraulic systems pioneered by Lotus back in the 1980s and perfected by Williams in its all-conquering FW15C F1 car, Audi is employing advanced 2kW electric motors at each corner to alter the damper settings every 15 milliseconds to iron out the ride, according to the head of the A8’s suspension development, Thomas Muller.

Rear-steer, active diff, air suspension: tech galore on 2017 Audi A8

Speaking exclusively to CAR, Muller explained that the active suspension is just one element in the car’s chassis dynamics that also embraces the air suspension, steering, rear-wheel steering, ESP, quattro all-wheel drive and active rear differential managed by a single powerful chassis electronic control unit (ECU).

With ±5° rear-wheel steering the A8’s turning circle is reduced to 11.4 mtrs, 90 cms less than the outgoing model and 20cms less than an A4; this not only makes manoeuvring in tight, urban spaces easier, says Muller, but enables quicker and more stable lane-change especially at speed.

The all-wheel steering shifts the point of rotation towards the rear wheels resulting in less lateral head movement for back seat passengers.

Active suspension ‘three times more efficient than a hydraulic system’

But it is the active suspension that really enthuses Muller. In its normal state the car sits on the air suspension, the dampers powering up only when required. As such, energy consumption is minimal: ‘At highway speeds it’s about 20W, on rough roads 250W and lapping the Nürburgring consumes 400W, about two to three times more efficient than a hydraulic system.’

Key to this is a novel belt drive linking the ‘strain wave gear’ and the motor; the former allows a very high 1:80 ratio thanks to its unique design. Incidentally this technology was first used in the 2007 A4’s steering set-up.

The active suspension is controlled via inputs from the forward-facing ADAS camera that ‘reads’ the road surface, transmitting signals to the control to raise or lower the suspension accordingly to cope with sleeping policemen or shallow pot holes, as well as a myriad of electronic sensors. The system has the capability of generating 16kN per second and, when combined with a bandwidth between zero and 6Hz, means the damper is being altered every 15 milliseconds.

As well as smoothing out longitudinal movements, body roll under hard cornering is halved as higher g-forces are encountered, giving the new luxury saloon a sense of agility ‘you wouldn’t expect’, claims Muller.

Active suspension could help lift occupants out of harm’s way in a side impact

It’s not all about comfort, though, there’s also a safety element. By linking in the pre-sense side sensors the suspension will jack up the ride height so that any side impact is taken by the sill structure and cross car beams rather than the door(s).

This is just the beginning of the development, says Muller, revealing that Audi is studying vehicle behaviour like ‘carving’ where the car leans into the corner to see what effect that has on the driver, passengers and vehicle safety.