► Audi is electrifying more than just its engines

► E-turbos, electro anti-roll bars and more

► We explain the key tech transforming your next Audi

Increasing the level of ‘electrification’ in cars is moving far beyond replacing the dirty old internal combustion engine with batteries and an electric motor. Premium car makers such as Audi are hurrying to upgrade their on-board electrical systems, in order to support additional hardware that tantalisingly promises not only improved efficiency but increased performance for petrol and diesel models as well.

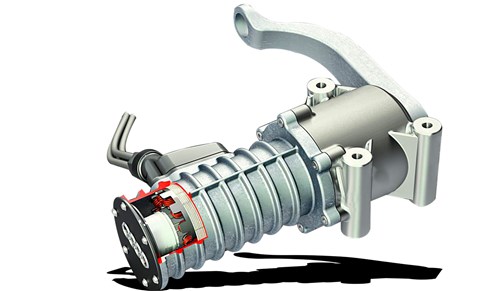

Electric turbocharging is the limelight-friendly poster child for this process. Already shown on the TT Clubsport concept and RS5 TDI technology demonstrator pictured here, it’s easy to see the benefit of spinning up a turbo without recourse to exhaust gases; instead of having to wait for the necessary build-up of pressure you can just turn it on, like a light switch. But doing so requires extra electrical power, hence the importance of 48-volt automotive electrical systems. Capable of handling four times the juice of current 12v set-ups and working in cahoots with a tiny lithium-ion battery, 48v offers the opportunity to electrify unexpected elements of the suspension too, in addition to delivering next-level ‘mild hybrid’ stop-start functionality via the use of a ‘belt starter generator’ in place of a conventional starter motor.

More fuel savings, more performance and a sharper chassis: can it possibly be true? Volkswagen Group certainly thinks so, and is keener then ever to prove its engineers can do more than write clever emissions code. The Bentley Bentayga already features 48v electromechanical active anti-roll technology, and Audi expects to have its version of this tech in showrooms alongside electric turbocharging next year. Ingolstadt is also exploring the potential of electromechanical rotary dampers for application further down the line. Maybe the pessimists will be driving electric cars – of sorts – earlier than they thought.

1) Electric turbos

The problem with conventional turbochargers is lag: they can’t boost engine airflow until there’s sufficient exhaust pressure to spin the turbine. To overcome this low engine-speed problem, Audi plans to add an electric turbocharger, which can start compressing air in as little as 250 milliseconds. Added to conventionally blown six- and eight-cylinder twin-turbo engines, Audi hopes to eliminate lag, deliver more explosive standing start performance and reduce the number of times you reach for a downshift.

2) 48v ‘mild hybrid’ with belt starter generator

‘Mild hybrid’ is another term for stop-start. 48v will nearly double the capabilities of next-gen 12v systems, by saving 0.7 litres of fuel per 100km, recuperating up to 12kW of energy and coasting for up to 30sec without troubling the sparkplugs. Plus it will be smart enough to adapt to different situations: smooth restarts as you pull away from grandma’s, or abrupt power-ups to help make that roundabout gap. The clever belt starter generator is fast-acting, not having to wait for the engine to be fully stopped before restarting – unlike today’s systems.

3) Electromechanical active anti-roll (eAWS)

Audi’s electromechanical active anti-roll system places an electric motor and three-stage planetary gearbox between the two halves of the stabiliser bar – allowing it to not only vary the amount of anti-roll the bar generates, to help level the car under a variety of cornering scenarios, but also decouple the two sides when no anti-roll capability is required, to boost comfort. So far so conventional. The difference is that the electric motors double as generators to recuperate energy as well as consume it, making them much more efficient. On a bumpy road, they become practically self-sufficient, saving fuel. They also operate at lower speeds and without the additional maintenance and environmental impact of hydraulic fluid

4) Electromechanical rotary dampers (eROT)

Conventional hydraulic shock absorbers could be replaced by a set of gears and an electric motor at each corner. There are packaging advantages, and as with every other on-board electric motor these rotary damper units can also be used to recuperate energy – and like electric anti-roll they do even better when the going gets rougher. Audi reckons the savings could be as much as 5g/km CO2. Suddenly, taking the B-road home could prove more efficient as well as more fun, especially since the ability to instantly vary the electric motors’ resistance can help balance compliance against body control to an extent that is simply not possible today. The bad news is that EROT is still at the prototype evaluation stage.