► We take a look at how Volvo’s ‘PowerPulse’ works

► Aimed at minimising turbo lag and boosting power

► Doesn’t require complicated electrical systems

Have the Swedes cracked the perennial issue of turbo response in diesel engines? While Audi tinkers with electrically powered boosters and BMW pursues triple turbos, Volvo boffins have come up with a simple alternative: compressed air.

Called ‘PowerPulse’, the patented system is fitted to Volvo’s latest D5 diesel engine and will be offered first in the new V90 estate. It’s being touted as a quickly available, cost-effective alternative to 48v e-booster systems.

‘We looked at e-boosters, but they require a 48v electrical loom, a larger alternator and an auxiliary battery, and that didn’t fit in with our new modular engine strategy,’ says Volvo development engineer Ragnar Burenius. ‘And nor do we think they are industrially mature yet.’

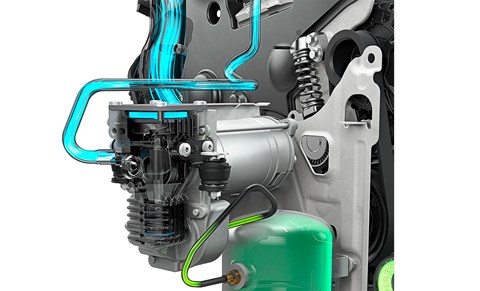

Using compressed air to spool up the turbos

Even though the D5 engine features two sequential Borg-Warner turbos – a 38mm turbo feeding a 53mm one – to help reduce lag this is further aided by a pulse of compressed air injected into the exhaust manifold, spinning the smaller turbo from idling at 20,000rpm to a fully operational 150,000rpm in 0.3sec.

Burenius claims the unique technology is ‘significantly’ cheaper than a 48v e-booster for the same result and could be scalable for different capacity engines. But could it work for a petrol engine? ‘It’s theoretically possible, although there would be a big question of how it would interact with the after-treatment system…’

Read on for CAR’s step-by-step tech guide to how Volvo’s system works:

1) Pressurised air tank

An electrically-driven compressor and a pressurised air tank are added to the powertrain in the space that houses the hybrid elements in other engine variants. Fresh air from the air filter is stored in the 2.0-litre tank at 12 bar and is constantly re-charged to ensure there’s a supply of pressurised air while driving or after being parked for any length of time.

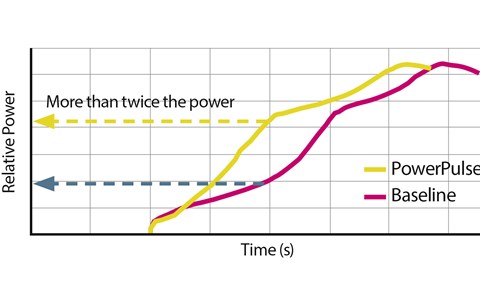

2) More power, delivered earlier

The key is when and where the power is delivered. The new engine delivers twice as much power within a second of acceleration from a standing start as the standard D5. It also reaches peak power earlier, marginally out-dragging 3.0-litre rivals over the first 60m.

3) Controlled by right foot

The injection is triggered by the driver’s throttle action, for instance at launch or during transient overtaking manoeuvres. A pulse of air, nominally at 12 bar and lasting about a tenth of a second, is injected into the exhaust manifold creating a very sudden pressure increase which speeds up the smaller turbine.

4) A tale of two turbos

The smaller, high-pressure turbo is predominant up to around an engine speed of 2500 to 2750rpm depending on driving conditions, ie, steady state acceleration or transient, before handing over to the bigger, low-pressure turbo which is now running at optimal speed of 160,000rpm for maximum boost.