► GKN’s new ‘e-axle’ concept explained

► ‘Twinster’ tech as seen on Focus RS

► Combined with a two-speed gearbox

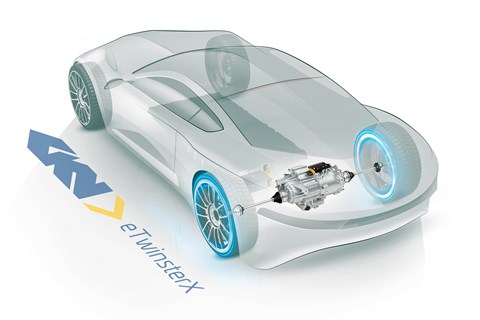

Global engineering firm GKN has revealed what it considers to be a breakthrough electrified rear axle system.

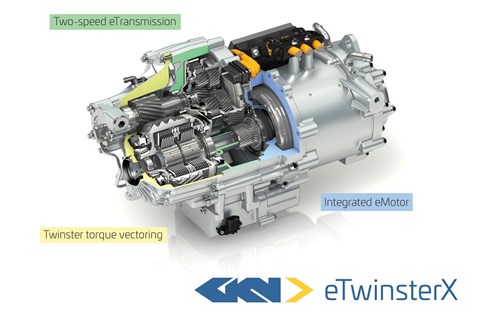

It incorporates so-called Twinster torque vectoring technology, as used in the Ford Focus RS, with a seamless shift two-speed transmission and an electric motor.

Why is it called eTwinsterX?

eTwinsterX is a combination of off-the-shelf GKN technologies, namely: Twinster torque vectoring (which uses two clutches to distribute torque between the wheels) and an electric motor-driven axle combined with a two-speed gearbox.

Multi-speed transmissions enable electric vehicles to deliver better launch performance using the lower gear, and more efficient high-speed driving with second gear, in this case up to a V-max of 155mph.

The system’s optimised shifting strategy, which keeps the e-motor operating close to its efficiency ‘sweet spot’, means that it can deliver greater maximum driving range as well.

Single-speed transmission vehicles typically have a mechanically-limited top speed, otherwise the e-motor would be operating in an inefficient part of its rev band. With a two-speed system, the higher gear allows the e-motor to operate at lower – and more efficient – rpm at higher speeds.

Precise torque delivery to individual wheels

Torque vectoring manages the distribution of torque to individual wheels, and can intelligently control vehicle dynamics. For example, enabling over-speeding of the outside wheel in a corner can induce a yaw-moment, helping to steer the vehicle towards a tighter cornering radius.

GKN Driveline’s Twinster torque vectoring solution is unique in that it replaces a conventional differential with a twin-clutch system that precisely adjusts the torque delivery to each wheel.

eTwinsterX electric axle – no need for a diff, or even for a reverse gear

The electric motor is used to launch the vehicle. Similarly reverse could be a thing of the past, as the electric motor is used to move the car backwards, as long as there is enough juice in the battery to allow it to do so.

When could this system reach showrooms?

GKN reckons the system could be in series production by the early years of the next decade and, because of its flexibility, would be equally suited to pure EVs as well as any other form of hybrid.

Theo Gassmann, GKN’s vice president of advanced engineering, says: ‘The combination of Twinster does a better job of four-wheel drive than a conventional mechanical system, because we have more freedom to deliver power to the second [rear] axle, even allowing negative torque.

‘Twinster with an electric motor gives full torque vectoring technology because it delivers electric power to each rear wheel for maximum response, traction and stability.’