► Uses MGU-H tech

► In next gen AMG cars

► Directly from F1

AMG is about to redefine the way we appreciate and drive turbocharged production cars, as it finalises development of a new turbocharger design derived from its F1 cars.

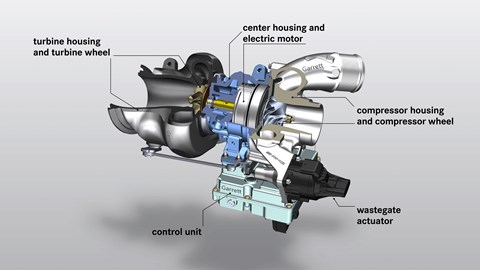

Built in partnership with Garrett, the system will allow AMG to fit larger, more powerful turbochargers to its cars, without increasing the amount of turbo lag.

The new design includes a small electric motor, about 4cm in size, that is integrated in the turbo’s shaft between the turbine and compressor. This unit spools the compressor wheel before it is aided by exhaust gases to build boost.

How a hybrid F1 engine works

AMG claims this system eliminates turbo lag – think of it as an electric anti-lag system. When a driver takes their foot off the throttle and begins braking, the turbocharger is able to maintain boost in preparation for when the throttle is applied once again.

Along with improved throttle response, AMG claims the system improves torque lower in the rev range.

AMG says the new technology is in the final stages of development, and will be put into production on one of the brand’s series production cars – debuting on a ‘next vehicle generation’, effectively ruling out its use in the facelifted Mercedes-AMG E63 or new AMG GT Black Series which are both expected to be revealed imminently.

Despite being operated by a 48-volt electrical system, AMG says the new turbo tech differs from the current crop of 48-volt electric compressors that are fitted to AMG’s 53 badge range, as it retains a conventional exhaust-driven side.

It’s been developed through AMG’s involvement in Formula 1 – where the Mercedes-Petronas squad has utterly dominated the sport since new turbocharged engine regulations were introduced in 2014.

Fans of F1 would be aware that a similar technology to what AMG will be putting on its road cars is used in F1. Called the MGU-H (short for Motor Generator Unit – Heat) it uses heat from the engine’s exhaust gases to drive a generator placed in the middle of the turbocharger.

Where regenerative braking can put charge back into a battery by harvesting the kinetic energy used to slow a vehicle down, the MGU-H harvests exhaust energy, making the vehicle more efficient.

‘The MGU-H] can recover energy from the turbo, store it, and then use it to spin the compressor.’ Rémi Taffin, Renault F1 Team Engine Technical Director, told Motorsport.com in 2016.

‘If you look at a turbocharger, you’ll find a turbine at one end, and a compressor at the other. The exhaust gases are used to spin the turbine, which spins the compressor.

‘The MGU-H is located in between the two. So, when the hot gases spin the turbine, it also produces electricity that is stored in the battery. And when the car accelerates, the electricity is used to spin the compressor, providing immediate power.

‘There’s no turbo lag. Power application is immediate, like with any normally aspirated engine.’

Outgoing AMG boss Tobias Moers says the F1 tech will allow Mercedes-Benz’s performance division to elevate its ‘turbocharged combustion engines to a previously unattainable level of agility’.

This article originally appeared on whichcar.com.au