► Lambo’s Active Wheel Carrier tech

► CAR gets a demonstration and drive

► Launches in Huracan replacement soon

The Nardo Handling Track in southern Italy is 3.9 miles of mostly fast or very fast turns nestled at the bottom of the Nardo Ring like a wonky arch in a goldfish bowl. For a pro driver to lap 2.8 seconds faster here in virtually the same car might require upgrades like stickier tyres, stiffer suspension and upgraded brakes.

The Lamborghini Huracan Evo RWD test mule I’m driving has none of this, and even the stability control is off, but it has achieved that same improvement with the flick of a switch. It’s a huge gap.

Now Lamborghini chief technical officer Rouven Mohr wants me to feel the difference before he’ll reveal the genius tech his team’s been working on ahead of a production debut on ‘future super sports cars’ (not very subtle code for the Huracan’s hybrid successor).

I head out to a slalom and steering pad with ex-racer and Lamborghini tester Nicolo Piancastelli in the passenger seat, knowing only that the new system is meant to help take the existing LDVI (Lamborghini Dynamic Vehicle Integration) technology to the next level. LDVI is the electronic brain that debuted on the Huracan in 2015 and made a recent leap with the new Revuelto; it predictively mediates between various chassis, powertrain and steering systems.

Weaving down the slalom, the standard car’s front end is incredibly reactive to steering inputs, partly because the rear is relatively unstable – you lean on what feels like a hard, bladed edge behind you, almost like ice skating. It’s agile but edgy. Building to a steady 70mph on the steering pad, I turn in, lift the throttle abruptly and the Huracan arcs first into a slide, then a tankslapper requiring multiple corrections. Yep, definitely edgy.

We pull over, Piancastelli flicks a switch near the steering wheel and seconds later I’m struggling to compute what’s just happened.

Through the slalom the front feels exactly the same, the suspension appears to allow just as much roll over the rear axle, but the blade-like feeling at the rear has vanished, replaced by a more cushioned sensation. ‘I can see you are immediately making more aggressive steering inputs,’ comments Piancastelli. I am.

On the steering pad the system makes the Huracan much more stable, but it also pushes more into stubborn understeer, then appears to actively counter the smaller tankslapper I eventually induce by dissipating weight transfer in a way not dissimilar to stability control, if without the jolty braking.

Mohr grins as I feed back, and he confirms the system is exclusively focused on the rear and that there are no new active adjustments influencing suspension control. ‘Well, any ideas?’ he asks. I suggest maybe rear-wheel steering (already fitted to other Huracans, though), perhaps a new e-differential (the old one is mechanical). ‘Hmm, maybe…’

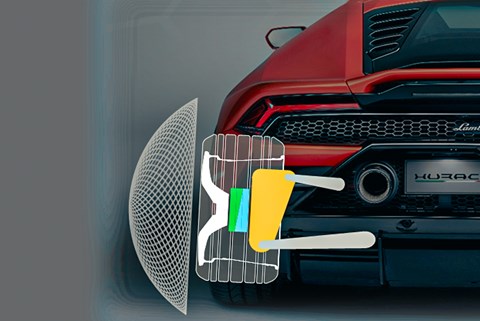

What I’ve actually experienced is Active Wheel Carrier, or a way to actively control the camber and toe of the wheel and tyre. Initially conceived at Audi, it has been developed by Lamborghini as part of a wider plan for Sant’Agata to forge a reputation as a tech trailblazer.

First, a quick refresher. Camber is how much the top of the wheels lean towards (negative) or away from (positive camber) each other when you view the car from straight ahead or behind. It’s a way to manipulate how much of the tyre’s contact patch touches the road.

Adjusting toe, meanwhile, makes a car either more responsive to steering inputs or more stable – toe-in is like standing with your toes pointed a little towards each other (more stable), toe-out being the opposite (keener to steer).

Normally camber and toe are set at the factory as a one-size-fits-all compromise. Under braking, cornering and acceleration loads on the car change, altering how the tyre interacts with the surface.

Active Wheel Carrier aims to remove the compromise by generating the maximum mechanical grip at all times. The key is a pair of new wheel hubs sandwiched between the suspension components and each wheel. Each hub features two eccentric cylinders connected by bearing packs – I pick a hub up and twist the cylinders in opposite directions like I might a Rubik’s Cube; when you’re driving an electro-mechanical system does the job.

The system can theoretically adjust by 60º in one second, and in practice allows adjustments of camber by +2.5º to -5.5º and toe by +/- 6.6º, which handily removes the need for a separate rear-wheel steering system. No word yet on weight, which they’re apparently working on, but Mohr doesn’t correct me when I say each unit seems to add about 6-7kg, and the system would be 20-25kg in total.

Benefits and potential benefits are myriad. Not only does the driver get more confidence from up to 25 per cent more mechanical grip from the same tyre, but tyres wear more evenly across their tread. That means a much softer and grippier tyre compound could be used with Active Wheel Carrier effectively offsetting the higher wear rates.

The system could also adapt to a wearing tyre, self-correct for alignment, and be calibrated for different modes and drivers, ranging from maximum stability to a full drift mode. Each wheel can also be individually adjusted.

This is not a completely new idea – you might remember Lewis Hamilton changing camber settings on the fly in his F1 car, for instance. But Mohr emphasises that there’s another crucial aspect to Lamborghini’s implementation of the idea. To avoid the peculiar feeling of camber and toe changing, there’s predictive ‘feed-forward’ software control.

This is designed to make the system more driver-orientated, with the driver ‘in the loop’, and electronics figuring out what he or she wants micro-seconds in advance, based on their inputs. To do this, LDVI also analyses the dynamic state of the car and projects that ‘into time and space’ to work out what the appropriate response would be – preparing for the weight transfer of a drifting transition, for instance. Mohr likens it to proprioception in humans, where neurons in muscles, tendons and joints feed back to the brain, helping us balance and co-ordinate movements.

‘If you want to decouple camber and toe and use it to its full potential, you need this forecast, otherwise you’d exploit only half of it, so the control strategy is the enabler,’ Mohr sums up. ‘It lets the driver achieve the limit in a way that before was not possible.’

This has taken endless hours of simulator time, because it’s only in a virtual environment that Lamborghini can cycle through multiple scenarios that can be exactly replicated time and again.

Now fully briefed about the technology I’m experiencing, I head out on the Handling Circuit, which is a fearsomely fast place whatever you’re driving, never mind a V10 supercar with stability control kicked into touch.

The track drive reinforces what I’d learnt earlier, but reveals more nuances. When I brake deep into a mid-speed left-hander with the system off, for instance, the rear wants to sweep round and tuck the nose into the apex – the car is alive and adjustable, but it does keep me on my toes. Even really fast flat-out corners that aren’t grip-limited feel heart-in-mouth.

We pit, flick the switch and head back out. With Active Wheel Carrier engaged I have more confidence to dig deeper into the power and push hard through the real commitment stuff, but some of the immediacy and reactivity of the previous laps is lacking, and on the first tighter corner I scrub into understeer. The rear end has more grip than the front (which now pushes wide as a result) and the system has been primed for maximum stability. But the fact I lap 4.41 seconds faster using the Active Wheel Carrier system is hard proof of just how effective it is. If there’s a caveat to that, it’s that this was my first visit to Nardo, so there was inevitably a learning process during my six total laps, but the fact is the system does let less experienced drivers shave more from their lap time than adaptable pros.

Crucially, this is just the beginning of a process that will introduce each element of the new LDVI system in turn, allowing the benefits to be properly analysed in isolation. The same system, for instance, could be applied to the front axle to hopefully combine a highly reactive front end with the more stable rear (and/or a wider, stickier front tyre could be fitted). A new tyre compound will also be developed to fully exploit its benefits. And new active aerodynamics will further tap the capability. That 2.8sec lap-time improvement will doubtless improve a mind-boggling amount more.

Today gives us just a glimpse of how it will drive, but on this basis it’s shaping up to be quite the thing.