► Your Volkswagen ID electric car briefing

► Full range of EVs both present and future

► Plus, the tech and the factory behind VW ID

Volkswagen’s come late to the electric car revolution, but since showing the ID Concept of 2016 it’s really started to get serious and is now a major player in the EV market. That concept became the ID.3 production car just three years later, and has laid the foundations for an entire ID range of electric VWs. Most of these are labelled numerically, but the ID. Buzz proves that Volkswagen isn’t limiting itself to that format.

VW’s switch to electric is hitting strides. In 2022, the brand sold 330,000 EVs – up by around 23 per cent over 2021. The new year will include the reveal of the new ID.7 saloon, and we should get more details on the upcoming superminis.

Speeding things up

However that doesn’t seem to be fast enough. According to a new statement, VW intends to ramp up its investment and also revamp its software strategy. The new five-year plan should eliminate lots of the delays and budget issues the company has already experienced around its electric car strategy.

What’s next?

Once complete, the ID range will stretch from one to seven, with space for niche additions like the Buzz minivan and Buzz Cargo commercial van. So far, all models of ID have been built on the Volkswagen Group’s MEB platform, which is also used by Audi, SEAT and Skoda. However, the Volkswagen Trinity project is already pointing to the next steps for the parent brand, and we’re expecting to see the first fruits of that in 2026 based on the new Scalable Systems Platform (SSP).

Trinity will launch with a flagship EV, and it may be built at a brand-new production facility at Wolfsburg – though the company is still debating whether or not to do so. Still, the Trinity will usher in a new generation of electric cars with a focus on longer range, increased autonomy, and a shift in the way cars are built and sold. More on that later.

Returning to the present, so-called performance variants of the ID range are also starting to appear, These are labelled GTX, denoting their supposedly sportier character, quicker acceleration and dual-motor, all-wheel-drive configuration. The first of these warmed-up EVs was the ID.4 GTX, and we’ve recently the ID.5 GTX – neither really feels close to the equivalent of a petrol-powered GTI, though.

Here are some handy links to navigate this article:

Electric Volkswagens – how it’s going so far

The ID brand got off to a bit of a shaky start – having established interest and created a huge waiting list, VW got the ID.3 to market so quickly the software wasn’t fully ready, leading to reports of lots of bugs. Over-the-air updates have delivered a relatively straightforward fix for this, though we also know at least a few cars were bricked as a result, requiring replacement hardware under warranty.

Teething troubles aside, Volkswagen’s push for electric mobility would certainly appear to have been successful during 2020, with the brand delivering almost three times as many pure-electric vehicles as it did the year before.

Despite the obvious challenges presented by 2020, VW delivered nearly 134,000 electric vehicles, and 212,000 electrified cars in total (including hybrids and plug-in hybrids). That’s an increase of 197% and 158% respectively.

VW’s Ralf Brandstätter (then chief operating officer, now CEO) said: ‘2020 was a turning point for Volkswagen and marked a breakthrough in electric mobility. We are well on track to achieve our aim of becoming the market leader in battery electric vehicles.’

In October 2021, VW reported more than 144,000 orders for the ID.3 to date, with 70,000 of those coming from buyers who hadn’t previously owned a Volkswagen. By the end of the year, Volkswagen had sold 263,000 EVs, with a further 106,000 sales of plug-in hybrid models contributing to 369,000 electrified vehicles in total.

That’s a 97% increase for EVs over 2021, and a 73% increase electrified – representing 5.4% and 7.5% of volume share (versus 2.5% and 4.0% the previous year).

However, since then, the war in Ukraine has caused further difficulties, compounding supply chain issues related to Covid and components, and interrupting production lines – including for VW’s ID models.

The ID range: Volkswagen’s EVs explained

The electric ID brand is as significant to Volkswagen as the Beetle was in 1945 and the original Golf in 1974. In their different ways, they transformed the company. ID’s job is to do the same at a time when VW is still being buffeted by the aftershocks of Dieselgate, ID itself standing for ‘intelligent design, identity and visionary technologies.’

Each of the ID models, which will range from A-segment through to a saloon, SUV and a seven-seater, will have ‘the interior space of the class above’, explained Andreas Köhler of the MEB’s electronic project management team.

With an anticipated 10 million vehicle sales across all VW Group brands during the first wave of electrification (and up to 22m by the end of the 2020s), there’s been considerable focus on component sharing and cost cutting. The all-steel MEB platform helps; it’s far cheaper than a lightweight aluminium alternative.

But as with all electric car makers, the big cost challenge for VW is in the less familiar area of battery costs. Volkswagen to not only needs to master the use of batteries but maintain a reliable, cost-effective supply of the raw materials, while being on the lookout for technical advances.

On sale: 2025

VW is building a small electric city car that will be called the ID.1. CAR first predicted the model in the summer of 2020, with the brand officially confirming the new model at its annual conference in March 2021. It’s slated to go into production in 2025 to replace the Up, with an entry price of around £17,000.

VW ID.2

On sale: 2025

We likely got our first glimpse of the ID.2 when VW pulled the covers off the ID.Life concept car at the 2021 IAA Mobility show (or the Munich motor show, to you and us). This compact car is due to go into production in 2025. The concept had a 54kWh battery good for a range of 248 miles, VW says, and the company is targeting an aggressive price point of just 20,000 Euros.

VW ID.3

On sale: now

The first of Volkswagen’s new ID electric car family, the ID.3 entered production in 2020. Equivalent in size to an electric Golf, and as significant to the company as the advent of that car, the ID.3 has successfully ushered VW into the electric age.

Priced from just under £34,000 and capable of a claimed range up to 259 miles per charge, the ID.3 is good to drive, offers plenty of performance and carries off a futuristic vibe without feeling alienating or being impossible to use (though VW’s latest infotainment system comes pretty close).

What’s more, it’s designed to be net carbon neutral, so even the way it’s manufactured is intended to take care with resources and the planet.

On top of that, VW has dreamt up an ID.3 convertible. While just a flight of fancy for now, Brandstätter and CEO Herbert Diess have both expressed their interest in developing one.

Read our VW ID.3 review

VW ID.4

The second model in Volkswagen’s ID range of electric cars, the ID.4 is a crossover SUV based on the firm’s electric MEB platform.

It takes inspiration from the ID Crozz concept of 2017 and arrived internationally in 2021. Battery options are 52kWh and 77kWh, with power outputs of between 146bhp and 201bhp, and range spanning from 213 miles to 322 miles depending on the configuration you choose.

These single-motor, rear-drive cars are joined by high-performance GTX and GTX Max variants with dual-motor, all-wheel-drive outputs of up to 295bhp and a range of up to 301 miles.

As for charging, VW claims a top-up from five to 80 per cent takes as little as 38 minutes when using a 100kW DC charger.

Read our VW ID.4 review

VW ID. 5

On sale: now

Another model inspired by the ID Crozz concept. The ID.5 is a coupe-SUV version of the ID.4, with a shallower and sleeker silhouette yet still plenty of practicality inside.

Going on sale in the first few months of 2022, the ID.5 arrives with three power outputs and only the larger 77kWh of the ID4’s two battery options. VW claims up to 323 miles of range, dropping to 298 miles for the more powerful, dual-motor GTX model.

Read our VW ID.5 review

VW ID.6

On sale: not in the UK

The VW ID.6 is purely aimed at the Chinese market – so much so, that it won’t be on sale anywhere else. As you can probably tell from the name, the ID.6 will slot above the hatchback-sized ID.3 and the more crossover sized ID.4. It’ll seat seven.

The familiar 58kWh and 77kWh battery options from other ID models are seen here too, but with claimed range increased to 271 and 365 miles respectively. Maybe in China miles are shorter?

VW ID.7

On sale: 2023

The new ID.7 was first revealed at the 2023 CES show in Las Vegas, with Volkswagen of America taking the lead on launching it.

The new ID.7 brings with it a new version of VW’s infotainment system (which is much welcomed) and some additional upgrades to right the wrongs of other cars in the range. We’ll see the full production version later in 2023.

Read our early Volkswagen ID.7 review here

VW ID. Buzz

On sale: now

Volkswagen has brought its Microbus minivan back from the dead – as a heavily stylised, all-electric fashion wagon. We first saw the reborn MPV as the ID. Buzz concept back in 2017 but we had to wait until 2022 for the production version to reveal itself. We’ve driven the new Buzz here.

Again based on the scalable MEB platform, the ID. Buzz is the first production model to break the numerical naming convention. It comes in a choice of lengths and between five and seven seats, depending on the configuration. Combining a 77kWh battery pack with the 201bhp motor option, driving range is predicted to be at least 250 miles – and more powerful versions, including four-wheel drive variants, will follow.

You can also have the Buzz as a van called the ID. Buzz Cargo – though the fashion thing doesn’t make it super useful, as payload is well under a tonne.

VW ID Space Vizzion

On sale: 2024

Codenamed Aero 2, the production version of the ID Space Vizzion – an all-electric estate – will likely arrive in 2024.

A Vizzion but with more space – see what they did there? – this EV is an estate version of the regular ID Vizzion concept from 2018.

VW ID. Buggy

On sale: probably never

After the ID range of cars reaches full fruition (meaning everything from ID.1 to ID.7), Volkswagen is considering adding more niche EVs to its range to inject a bit of fun into the mix.

Volkswagen brought out a concept to resurrect the beach buggy as an electric ID model, with CEO Herbert Diess saying at the 2019 Geneva motor show that it was considering launching it by collaborating with third parties to make such niche cars viable. However, CAR insiders say the project has been canned, after a deal with Aachen-based e:Go Mobility fell through due to e:Go filing for insolvency.

VW ID Ruggedzz

On sale: 2025? (But see below)

Instead of the ID. Buggy, VW is considering launching a tough, small 4×4 codenamed the ID. Ruggedzz in 2025. Designed to be a rufty-tufty off-roader with e-power, the Ruggedzz will be cheap to build, easy to clean, flexible and affordable to run – aimed at the young outdoors and lifestyle crowd.

As you might guess from the description, this project could, however, be handed over to Skoda.

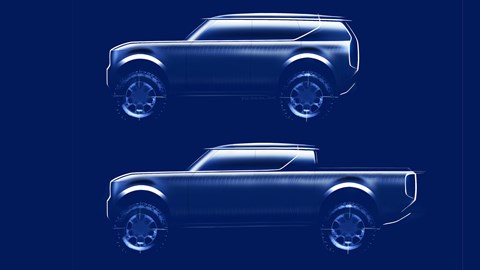

Scout electric SUV and pick-up

On sale: 2026 in the USA only

Not part of the ID family and targeting the USA only, in May 2022 VW confirmed plans to resurrect the Scout marque as a new electric ‘rugged-SUV’ and pick-up brand.

This move is intended to support VW’s recent turnaround in the American market, with Group chairman Diess saying: ‘Electrification provides a historic opportunity to now enter the highly attractive pick-up and R-SUV segment as a Group, underscoring our ambition to become a relevant player in the US.’ The first Scout prototypes will begin testing in 2023, with production set for 2026.

Set to be designed and built in the USA as well, ‘the electrified Scout brand will be built upon a new technical platform concept which brings new pick-up and RUV credibility beyond the existing Volkswagen Group portfolio.’ Both markets are key to profitability in the States, and will see VW going up against the likes of the Ford F-150 Lightning and Bronco.

What is Volkswagen Project Trinity?

The next step of the electric onslaught. While the ID range is the start, VW says Trinity will be all of the elements it’s developed in the first range of cars boiled down into one entity, arriving in 2026. It’s linked to Audi’s Project Artemis but, while Audi’s project is more for developing electric luxury cars for itself, Porsche and Bentley, VW is focusing on the accessible end of the market. ‘This technology must not become the preserve of a select elite, which is why we are scaling it to make it available for many people,’ VW’s Ralf Brandstätter said during the 2021 annual conference.

Tangible details and imagery are scarce, but VW says Trinity will offer Level 2+ autonomous driving from launch (already the market standard, really), with the technology in-built to upgrade that to Level 4. On top of that, Trinity will be the framework for driving forward Car-to-X technology, allowing all of the brand’s cars on the road to talk to each other – that detail could make a huge difference to Level 4 autonomy being safe and successful.

As well as Level 4 autonomy and a claimed range of over 400 miles, Project Trinity will bring about a change in how VW cars are sold as part of the company’s ACCELERATE strategy. This will see the Trinity delivered in a largely standardised form, with the owner able to purchase and unlock additional software features at a later date – a bit like adding extra functionality to a smartphone by purchasing an app.

Trinity will be the first vehicle built on VW’s new Scalable Systems Platform (SSP), which will be even more customisable than the current MEB platform used by ID models. VW is projecting some 40 million vehicles will use SSP over its lifetime.

In April 2022, Volkswagen announced a 2 billion Euro investment into the production of the ‘ground-breaking’ Trinity electric model, including the creation of a brand new production facility at the firm’s famous home site of Wolfsburg. This is in addition to plans to start manufacturing the ID.3 in Wolfsburg as well as a means to keeping up with demand.

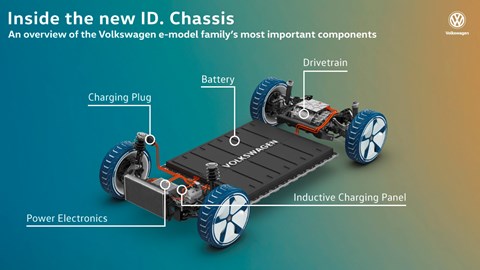

Electric Volkswagens: ID EV tech explained

With an anticipated 10 million vehicle sales across all VW Group brands during the first wave of electrification (and up to 22m by the end of the 2020s), there’s been considerable focus on component sharing and cost cutting. The use of an all-steel platform will help; it’s far cheaper than a lightweight aluminium alternative.

But the big cost challenge will be in the less familiar area of battery costs. As VW makes the transition from internal combustion to electrification, it needs to not only master the use of batteries but secure a reliable, cost-effective supply of the raw materials, while being on the lookout for technical advances.

VW’s Christian Senger told CAR: ‘Today 40% of an EV’s cost is the battery, and while the cost of components like electric motors and power electronics has halved we won’t achieve cost parity until 2025, not before. We have to reduce battery costs but in the meantime reducing complexity by simplifying the architecture is a move in the right direction.’

Like the MEB, the battery pack is modular. Hence the choice of variable lithium ion battery sizes even within the same ID model range. VW is using both prismatic and pouch cells for the most efficient packaging and easier handling. Crucially, because the ID range will be built on a global scale, including the USA and China, the batteries are ‘cell agnostic’ – able to accommodate locally produced cells.

According to Dr Armin Modlinger, responsible for developing cell technology for all the VW brands, solid-state batteries – with their improved safety and higher energy density – are not likely to appear until the end of the 2020s.

But ID is not just about electrification. They are the first VWs to be permanently connected to the cloud via 4G, and are being future-proofed for 5G. VW has developed a completely new end-to-end electronics architecture, branded E3, together with the new vw.OS operating system allowing the car’s software to be remotely updated.

A trio of separate application servers control various functions on the car: an infotainment server for third-party apps; an autonomous driving server; and a third server that is only accessible via VW’s digital platform.

How will you charge the ID range?

VW is part of the Ionity partnership with Daimler, BMW and Ford, which plans to open hundreds of charging sites with an average of six charge points per site across Europe. As of December 2021, there are 1,538 Ionity chargers at 388 locations across Europe, with a further 37 locations under construction. Ionity stations are able to charge at up to 350kW and 920 volts, exceeding what most electric cars are currently capable of receiving.; as demand and technology evolve, these will be able to charge at up to 350kW and 920 volts.

Senger dismissed concerns about battery recycling and the prospect of a dead li-ion battery mountain, revealing that VW is working with both universities and industry to develop recycling processes that will recover 97% of the batteries’ chemicals, although that is unlikely to emerge before 2025 when there are sufficient EVs on the road to make it financially viable.

‘Before then we could just replace any cells that fail and rebalance the battery or remove the battery and use it for stationary storage – there will be a huge market for this as the pricing is higher than in the automotive value chain.’

Credit where it’s due: hasn’t VW been forced into this by Elon Musk and Tesla?’ Senger says: ‘Tesla proved that people like EVs and that it’s not just about being CO2 compliant. If Model 3 had been on time – yes, that would have been a serious threat.’

Further electric car reading

The best electric cars and EVs on sale today

How much does it cost to charge an electric car?

The best hybrids, plug-ins and PHEVs

Wireless electric car charging